High-Pressure Homogenisers have actually been utilized more and more commonly, with the development of biomedicine, petrochemical, and food industry, as well as various other fields. The development of the laboratory tool industry additionally gives a selection of homogenizers with different features for the laboratories in the above-mentioned industries. So just how can we efficiently make use of a High-Pressure Homogenizer? This write-up will certainly bring you the response.

High-Pressure Homogeniser– Classification Application

Firstly, we need to select the most ideal High-Pressure Homogenizer for you according to your objective of use. A High-Pressure Homogenizer is only excellent if it fulfills your demands for experimental tools. To make it less complicated for you to select the High-Pressure Homogenizer that suits you, I will certainly give the classification of High-Pressure Homogenizer.

1. According to the framework kind, it is divided into upright important homogenizer and horizontal combined homogenizer. The previous is normally ideal for small and also medium-sized tools (power listed below 45kw); the latter is suitable for large tools (power above 45kw). At present, most residential manufacturers produce upright indispensable homogenizers. This kind has a portable framework, a gorgeous look, and a tiny footprint.

But for larger devices, security becomes a major problem. The supposed straight combination homogenizer describes the relatively independent blocks of electric motor, gearbox, crankcase, lubrication terminal, etc, as well as are dispersed on the exact same degree and are linked right into one body with belts (wheels), couplings, oil pipelines, and so on. The entire machine has a low center of gravity, steady operation, and also convenient maintenance.

2. According to the reciprocating times of the bettor per minute, it is divided into ordinary-type homogenizers and also low-speed-type homogenizers. The rate of the crankshaft of the homogenizer (that is, the reciprocating frequency of the plunger) is just one of the most important aspects that establish the performance of the whole device.

When it comes to the same product, processing accuracy, structure, etc, the reduced speed within a certain range, the wear degree of each rubbing set (such as shaft and also bush, plunger and seal, and so on) The damages degree of parts (such as valve core, valve seat, etc) is significantly minimized in the same period, and also the security of equipment operation is additionally significantly enhanced. Therefore, this series is especially appropriate for celebrations of long-lasting usage.

3. According to the control mode, can be separated right into hands-on control kind, manual hydraulic control kind, as well as automated hydraulic control kind. Today, the manual control type controls the market. If the entire production line is immediately regulated, a fully automated control homogenizer can be chosen.

4. According to the placement of the homogenizer on the assembly line, it can be split into upstream homogenizer as well as a downstream homogenizer. Normally, the homogenizer made use of before sanitation is called an upstream homogenizer, and the homogenizer used after sterilization is called a downstream homogenizer.

Normally the previous can utilize a Basic High-Pressure Homogenizer, while the latter should make use of a clean and sterile homogenizer. The supposed aseptic homogenizer is to separate the leakage factor of the dynamic seal at the plunger of the homogenizer and also the leakage point of the static seal of the inlet and outlet from the ambiance via heavy steam (or superheated water). Such a homogenizer can be utilized as an aseptic Sterilization device is made use of after sterilization.

Factors Affect the Efficient Work of High-Pressure Homogeniser

Stress

High-Pressure Homogenizer going into a homogenizer can differ in bit dimension, thickness, shape, and general pH– facets that can create unique temperature and also pressure levels of sensitivities that ought to be plainly comprehended before processing. Rapid depressurization after high pressure can lyse cells through pressures such as fluid shear, which has several uses, consisting of DNA purification and protein recovery. The user should identify the uniform pressure that will certainly achieve these particular cell lysis, as stress that is too reduced may not be effective.

Sample kinds need different homogenization pressures for cell lysis. As received in Figure 1 below, some frequently researched bacteria require various lysis stress.

Based on the above, it is critical to identify the one-of-a-kind cell lysis stress for a specific example. High-Pressure Homogenizers allow the user to adjust the homogenizer regulates to the proper stress to achieve the wanted outcome while minimizing temperature level surge; an occasion that can be important when managing warm sensitivity.

Stress and also temperature level directly affect each other. As a basic regulation, a 1000psi (69 bar) boost in stress will cause a 1 ° C rise in temperature level, which might adversely influence the homogenization outcome – so it is necessary to regulate the pressure.

| Species | Pressure |

| Escherichia coli | 10-15000psi (690-1030bar) |

| Saccharomyces cervisiae | 25-29,000psi (1,700-2,000bar) |

| Pichia pastoris | 23-27,000psi (1,500-1,800bar) |

Temperature

More challenging samples typically call for higher stress for processing. In the case of DNA or healthy protein isolation, the optimal uniform stress for a specific sample mustn’t cause temperatures high enough to damage sensitive intracellular products.

The stability of water-in-oil emulsions can also vary substantially with temperature level since certain physical homes of the oil, water, interfacial movies, as well as surfactant solubility are conveniently impacted. An increase in temperature brings about the destabilization of the crude oil/water interfacial film. It can likewise alter the rate of interfacial movie formation, along with the compressibility of the film.

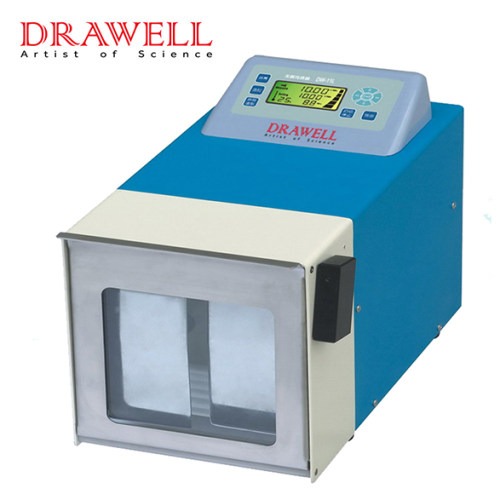

Therefore, an increase in temperature level may bring about a boost in oil thickness and also thus an increase in emulsion thickness, so it can straight and also dramatically alter the top quality of the final product, as the optimal viscosity of the emulsion is always vital. The Drawwell High-Pressure Homogenizer gives precise temperature control through compatibility with cooling-down coils and sanitary heat exchangers.

Passes

High-Pressure Homogenizer is important to keep in mind that some items need higher co-opting pressures to proceed; nonetheless, these pressures can damage sensitive items. For example, proteins might be denatured.

In cell disturbance, enhancing the variety of passes while lowering the pressure can accomplish the maximum yield of active and also feasible products in most cases. This has likewise been demonstrated in other applications such as solutions, liposomes, and also diffusions, where raising the number of passes within reasonable limitations may improve product security.

Working this way can have its drawbacks, as in the past numerous High-Pressure Homogenizer that consisted of “fixed” homogenizer shutoffs tended to clog when running viscous materials. Additionally, machining at such high pressures can cause valve deterioration, which, like clogging, costs the customer time and money in repair as well as upkeep.