XRF (X-ray fluorescence) mineral analyzers have revolutionized the field of mining and materials analysis, offering a powerful tool for understanding the composition and characteristics of various minerals. As industries seek efficiency, accuracy, and cost-effectiveness, the significance of XRF analyzers becomes increasingly evident. However, with their growing popularity, questions arise regarding their superiority over other mineral analyzers, their applications in mining, and the factors contributing to their seemingly high costs.

In this article, we delve into three common questions surrounding XRF mineral analyzers. By exploring the unique benefits of XRF, its applications in mining, and the factors influencing its cost, we aim to empower you to make informed decisions for your mineral analysis needs.

Comparaed with other Mineral Analyzers, Why Choosing XRF?

In the diverse world of mineral analysis, a multitude of techniques vie for attention. However, X-ray fluorescence (XRF) analyzers stand out for their unique combination of advantages, making them a popular choice across various industries and research fields. While each technique has its strengths and weaknesses, let’s compare XRF to other common methods to understand its clear edge:

| Feature | XRF | IR Spectrometer | Raman Spectrometer | Electron Microscope | XRD Analyzer |

| Non-destructive | Yes | Yes | Yes | No | Yes |

| Portable | Yes (options available) | No | Yes | No | No |

| Analysis speed | Fast (minutes) | Moderate | Moderate | Slow | Moderate |

| Element range | Wide (most elements) | Limited (mainly light elements) | Limited (specific elements) | All elements | Most elements |

| Information provided | Elemental composition | Functional groups | Molecular bonds | Elemental composition + morphology | Crystal structure + elemental composition |

| Cost | Moderate | Low | Moderate | High | High |

| Ideal applications | Field analysis, mining, quality control, environmental monitoring | Soil analysis, polymer identification | Gemstone identification, pharmaceutical analysis | Detailed morphology & composition, materials science | Crystallographic analysis, mineral identification |

While other techniques excel in specific areas, XRF’s unique combination of speed, portability, non-destructiveness, and versatility makes it a powerful tool for diverse mineral analysis applications. If you need a reliable and efficient way to unlock the secrets hidden within your mineral samples, XRF is a compelling choice.

What is the Use of XRF in Mining?

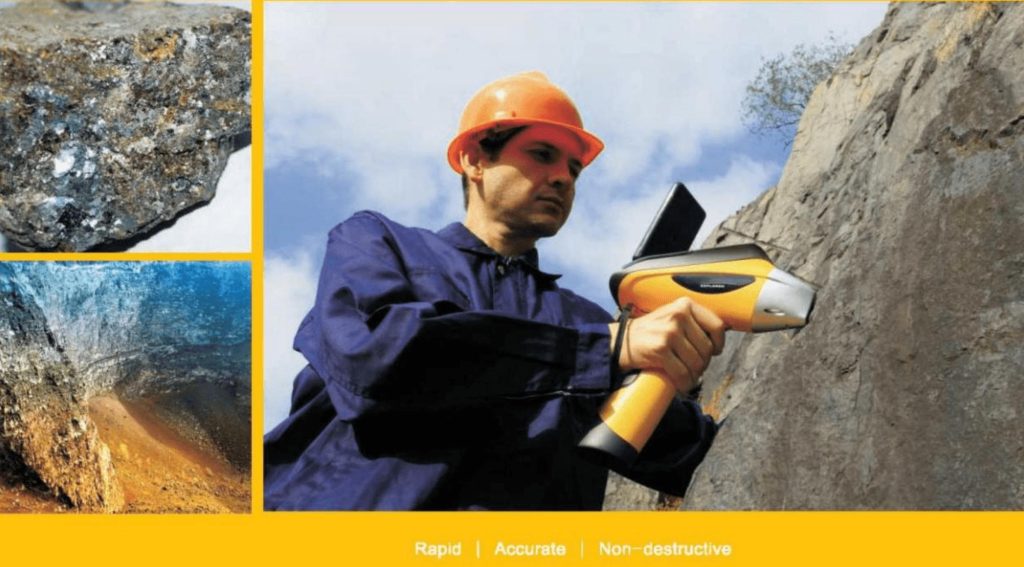

XRF is a powerful and versatile tool used extensively throughout the mining industry. It offers a fast, accurate, and non-destructive method for analyzing the elemental composition of various materials, making it incredibly valuable in different stages of the mining process. Here are some key applications of XRF in mining:

1. Exploration:

- Identifying mineralized zones: XRF analyzers can be used in the field to quickly identify the presence and approximate concentration of valuable minerals in rocks and core samples. This helps geologists focus their exploration efforts on promising areas and make informed decisions about drilling locations.

- Geochemical mapping: XRF data can be used to create maps showing the distribution of elements across an area. This information can be helpful for understanding the geological history of an area and identifying potential mineral deposits.

2. Mining operations:

- Grade control: XRF analyzers can be used at the mine site to determine the grade of ore in real-time. This information is crucial for optimizing mining operations by ensuring that only high-grade material is extracted and processed.

- Process optimization: XRF analysis can be used to monitor the composition of materials at various stages of the processing plant. This helps to ensure that the plant is operating efficiently and recovering the maximum amount of valuable minerals.

- Environmental monitoring: XRF can be used to analyze soil, water, and dust samples to monitor for potential environmental contaminants. This helps mining companies comply with environmental regulations and minimize their impact on the surrounding environment.

Overall, XRF is a valuable tool that plays a significant role in improving efficiency, accuracy, and sustainability in the mining industry. Its applications span across various stages, from exploration and discovery to extraction and processing, making it a crucial technology for mining operations worldwide.

Why are XRF Machines so Expensive?

XRF machines can range in price significantly, from tens of thousands of dollars to hundreds of thousands, depending on several factors:

1. Hardware Complexity

X-ray Source: The type and power of the X-ray source can significantly impact the price. High-performance sources provide better sensitivity and detection limits but come at a cost.

Detector: Different types of detectors offer varying capabilities. Higher-resolution detectors, essential for precise analysis of complex samples, are more expensive.

Other Hardware: Additional components like filters, collimators, and shielding contribute to the overall cost.

2. Application-Specific Features

Calibration: Machines calibrated for a wider range of elements or specific detection limits usually require more complex software and hardware, increasing the price.

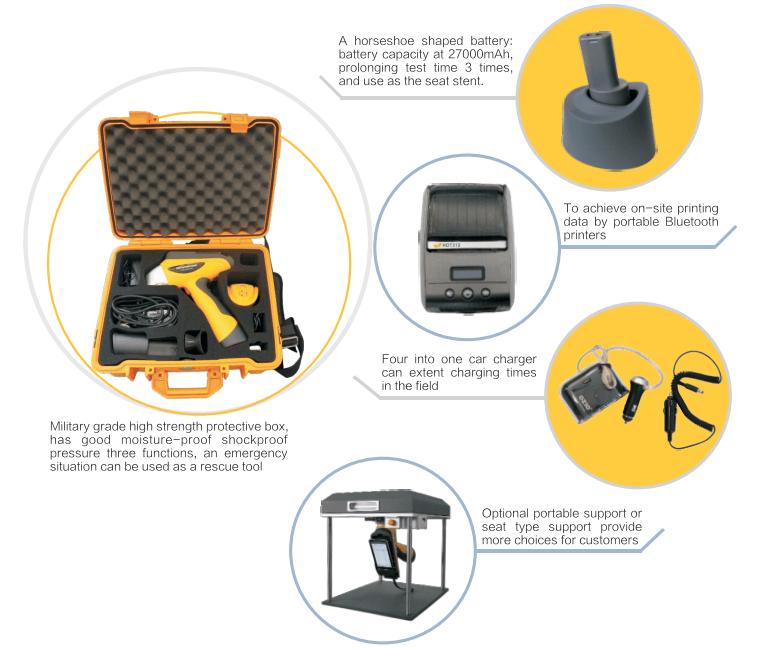

Portability: Handheld and portable XRF analyzers designed for field use incorporate ruggedized features and smaller components, impacting cost.

Software: Sophisticated software for data analysis, reporting, and regulatory compliance adds to the cost.

3. Regulatory Requirements

Meeting compliance standards like safety certifications and industry-specific regulations often requires additional hardware and software features, contributing to the price.

4. Market Demand

The limited number of manufacturers and specialized nature of XRF technology contribute to a niche market with less price competition.

However, it’s important to note that:

Cost doesn’t always equate to value. Consider the specific needs of your application and choose a machine with the optimal balance of features and affordability.

Alternative options exist. Budget-friendly handheld XRF analyzers with a limited element range are available for specific applications.

Leasing and rental options can be considered for short-term use or testing before a major investment.

By carefully evaluating your needs and exploring options, you can find an XRF machine that offers a strong return on investment for your specific mining operation.

Conclusion

In conclusion, XRF mineral analyzers stand out as indispensable tools in the realm of mining and materials analysis. Their versatility, accuracy, and efficiency make them a preferred choice for industries seeking comprehensive insights into mineral composition and quality. Despite their initial investment costs, the long-term benefits and efficiencies they offer justify their expense.

As technology advances and market demands evolve, the prominence of XRF analyzers is expected to grow further, driving innovations and enhancements in their capabilities. By embracing these advancements and understanding the nuances of XRF technology, mining professionals can optimize their operations, improve resource utilization, and ultimately enhance their competitive edge in the dynamic landscape of mineral extraction and analysis.