A vortex mixer is a simple laboratory device or device used to mix laboratory samples in test tubes, well plates, or flasks.

Brothers Jack A. and Harold D. Kraft developed the vortex mixer while working at Kraft Apparatus, Inc., a manufacturer of laboratory equipment, in Mount Vernon, New York. They use fairly simple processes to precisely stir samples to facilitate reactions or homogenize. Samples are simultaneously shaken and vortexed at high speed, designed to combine difficult samples such as dense particles and tiny or viscous samples, and can be used with tubes from 0.2 to 50 ml.

The device is compact, quiet, and equipped with multiple inserts to stir and mix samples of various sizes. A rapidly oscillating motorized drive shaft beneath the sample platform transmits orbital motion to the sample container located inside the mixer.

This results in turbulent flow – also known as vortices of the sample fluid. This is comparable to stirring but does not involve components protruding into the sample container. Microplates can also be affixed.

This is the first choice for numerous applications in microbiology and biosciences that require sensitive samples or high-throughput processes. Standard stirrers can only mix one sample container at a time. It cannot be combined with the liquid in the sealed bottle, and sometimes needs to be combined with the reagents of biochemical experiments.

In contrast, vortex mixers are usually designed with a minimal two-plate configuration, allowing the simultaneous mixing of large numbers of samples. Although their primary function is to mix samples and chemicals, vortex mixers can also be used to suspend cells.

How Vortex Mixers Work?

The drive shaft of the vortex mixer motor is placed vertically, and the cup-shaped rubber piece is mounted at a slightly off-center position. When the motor is running, the rubber part will make a rapid circular motion. When a sample is placed on a rubber sheet, vortices are formed in the sample as the motion is transferred to the liquid. This enables ferocious sample mixing.

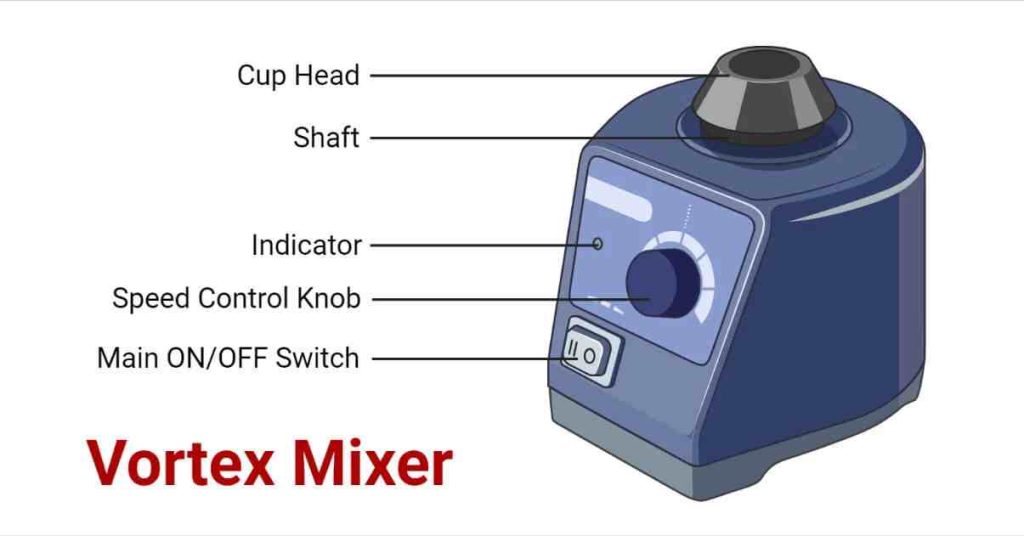

Parts of a Vortex Mixer

Main switch: The current required to run the vortex mixer is provided by turning on the main switch. It manages the power of the machine.

Motor: It is the core of the vortex mixer, which rotates in a circular motion. It sits just below the cup head. It creates a vortex effect in the liquid for proper sample homogenization.

Speed Control Knob: The speed control knob is located on the front panel of the machine. The rotation speed can be adjusted by turning the knob.

Operation Controller Buttons: The embedded control unit provides the ability to program the operation of the mixer.

Cup Tips: Cup tips are available in various sizes for quick mixing. For mixing various tube sizes, these heads are easily interchangeable with various-sized cup heads. The tube sits on the cup head to create a vortex.

The digital/pulse vortex mixer also includes all switches and controls and adds a display and pulse device.

Time Display: Displays the elapsed time (continuous mode) or remaining time (timer mode).

Speed display: Displays the moving speed of the vortex mixer.

What Are the Types of Vortex Mixers?

Variable Speed Vortex Mixer

It is convenient for the user to adjust the speed of the stirring process. This provides flexibility, as higher speeds can be used for more vigorous agitation, while lower speeds can be used for fine mixing of samples.

Constant speed vortex mixer

When the head is depressed, the fixed-speed vortex mixer starts mixing. Since the speed is fixed, it spins at full speed to create a powerful sample vortex.

Digital Vortex Mixer

The digital vortex mixer has a precise continuous function or pulse-on-demand function, and digital time and speed display. The speed range is from 300 to 4200rpm, covering a wide range from strong mixing to low-speed mixing. Accessories include a 250 ml capacity flask, a foam insert with a single microtiter plate, a universal platform, and a foam insert with microtubes.

Analog Vortex Mixer

The analog vortex mixer can be turned on at low speed for gentle shaking, or at high speed for vigorous vortexing of samples. You can choose between a touch mode that activates the mix when you press the cup tip and a continuous mode for accessories.

Mini Vortex Mixer

Mini Vortex Mixers are smaller and more portable. Suction cups on the bottom of the device add stability while creating barely audible vibrations. It is specially designed for stirring test tubes. To start shaking, simply insert the tube into the soft attachment. Once the tube is removed, the vibration stops. It is a robust mixer with a footprint of 100mm x 100mm and a top speed of 4,500 rpm.

Multitube Vortex Mixer

Flasks and tubes can be mixed in single or multiple tubes using a multi-tube vortex mixer. They don’t quite reach the speeds of more basic mixers, which carry fewer vials, since they have speeds ranging from 300 to 2,500 rpm. Accessories include tubular foam for holding tubes and flask foam for holding flasks.

Pulse Vortex Mixer

Intense pulsed vortexing activity produces excellent cell disruption for glass bead handling. A pulse vortex mixer can completely disrupt cells in a sample within minutes. Unique pulsating action reduces heat generation while enhancing mixing and destruction. The system has an easy-to-use container for measuring 5 mL or 2.0 mL microcentrifuge tubes.

Advantages of Vortex Mixers

- Various speed options guarantee that the desired speed remains constant throughout the process.

- Vortex mixers can hold up to a dozen vials, depending on the number of vials being mixed at one time.

- Furthermore, vortex mixers use minimal resources, expertise and resources.

- Vortex mixers ensure efficient and reliable mixing of samples.

Disadvantages of Vortex Mixers

If the tube is held incorrectly, there is a risk of spillage.

It does not work when combining solid and liquid or solid and solid ingredients.

How to Use the Vortex Mixer Correctly?

The front panel of the device contains all functional controls. The power switch on the left side of the panel has three positions TOUCH, OFF, and ON.

- Touch – The touch position turns on the mixer by pressing down on the mixing head, while the operation stops when pressure is released from the mixing head.

- ON – When the switch is on, the blender will run continuously.

- OFF – The mixer will stop running when turned to the OFF or TOUCH position.

- The adjustable speed control knob on the right side of the panel, when turned clockwise, causes the oscillation speed to increase at a non-linear rate of up to 3,400 rpm. Set the speed control to the lowest setting before starting the blender.

These steps, including operating procedures, are:

Turn the power switch to the TOUCH or ON position to start the unit.

Turn the speed control to the selected setting.

When the power switch is turned on, the bobblehead will start moving immediately.

When the power switch is set to the TOUCH setting, the device will kick in when anything is placed on the shaker head, using a small amount of pressure to depress it.

Once the pressure is relieved and the object is removed, the vibration stops.

Turn the speed control knob to the desired speed.

Disconnect the main switch.